Application of LED light technology to enhance plant growth.

The Toolangi Elite laboratory is evaluating new light management technologies to achieve the optimal plantlet growth and the improvements on minituber production.

A world leading potato variety germplasm genetic resource centre – an Australian first!

The establishment of a DNA library of all potato cultivars held in the tissue culture collection at Toolangi. When required the DNA library may be used as a reference database for DNA fingerprinting technologies to identify a given potato cultivar and/or the protection of intellectual property.

Installation of a new dedicated purpose-built growth room for the in-vitro tissue culture collection.

Toolangi Elite has Australia’s largest potato collection with over 430 public and private potato varieties and is an important genetic resource for the industry. To ensure the tissue culture collection is maintained in high health condition in a purpose-built growth room for secure and optimal storage of invitro material; all material is pathogen tested prior to entry and tubes are barcoded to further ensure variety purity. The new growth room utilises state-of-the-art LED light technology and is climatic controlled for longevity and stability of the collection.

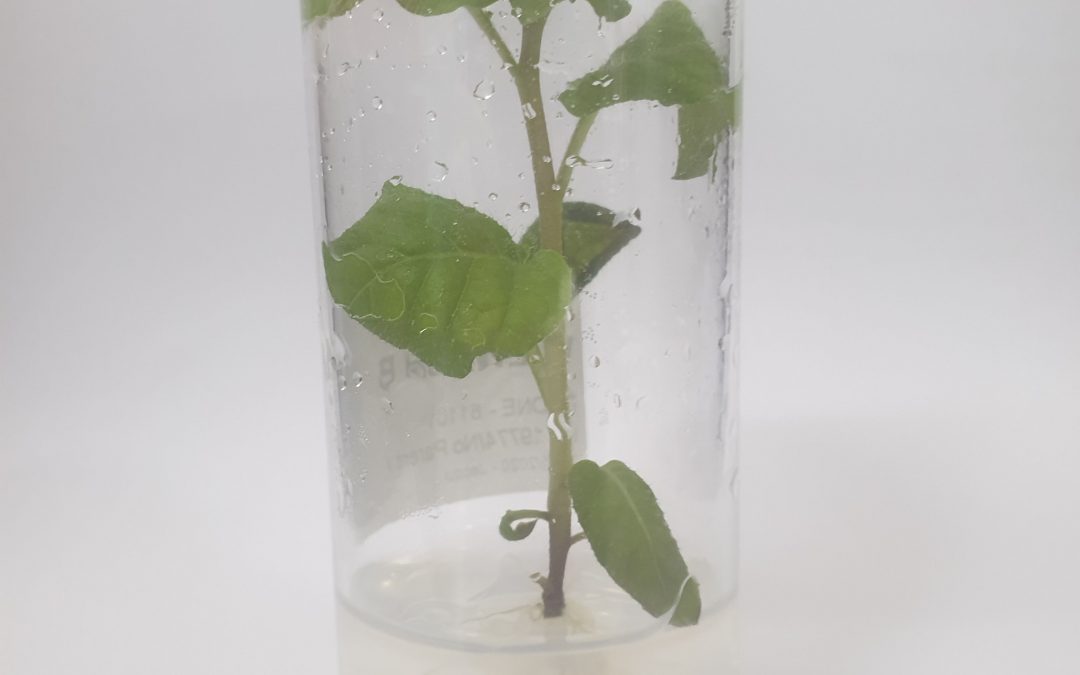

Media improvement to produce tissue culture.

The Toolangi Elite team are conducting internal experiments on the artificial media used to produce tissue culture. This is based on recent scientific literature published showing that tissue culture media can be modified to improve invitro plantlet growth and minituber production.

Application of precision technology and remote management for better minituber production

Toolangi Elite has installed specialty irrigation scheduling and cloud-based sensor technology that monitors all aspects of irrigation including water filtration and UV treatment systems which supply the polyhouses used to produce the minitubers.

The leading sensor technology has been applied to the minituber cool store to remotely monitor climatic conditions inside the store as well as monitor the associated infrastructure for any faults or errors.

The remote monitoring technology on both the irrigation systems and cool store instantly alerts staff to any key issues through email and SMS alerts, ultimately providing a risk management solution which safeguards production. The use of remote management technologies to monitoring and the capture of accurate data enables Toolangi Elite to better benchmark quality assurance and product performance. Importantly, the optimistation of storage conditions enables the better management of the physiological age of minitubers.

Recent Comments